Understanding Lean Six Sigma in the Indian Context

Exploring Lean Six Sigma for Indian Enterprises

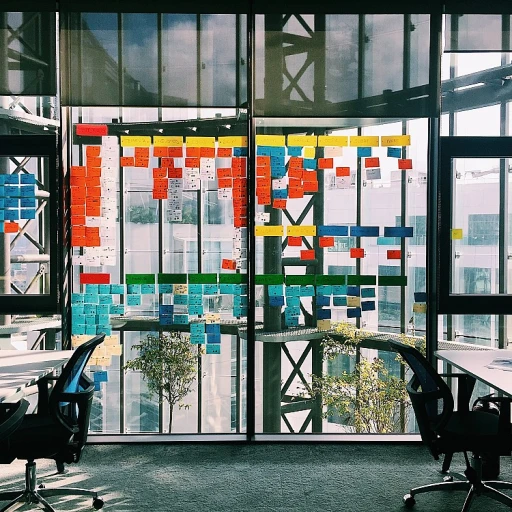

In today's competitive market landscape, Indian businesses are constantly seeking methods to enhance operational efficiency. Lean Six Sigma emerges as a comprehensive approach that combines the principles of lean methodology with Six Sigma's rigorous data analysis to drive process improvement and business growth. Lean Six Sigma focuses on reducing waste and improving quality. It leverages tools such as DMAIC (Define, Measure, Analyze, Improve, and Control), process mapping, and regression analysis to identify and eliminate inefficiencies. These sigma techniques help businesses streamline operations, cut costs, and boost productivity. For Indian enterprises, the adoption of Lean Six Sigma is transforming the way they operate. From manufacturing sectors to service-based industries, the lean sigma approach has become instrumental in refining processes and ensuring continuous improvement. A crucial facet of Lean Six Sigma is its structured problem-solving methodology, which empowers teams to address complex issues effectively. Indian companies are witnessing significant improvements, particularly in areas like quality control and process optimization. By understanding the nuances of Lean Six Sigma in the Indian context, businesses can tackle unique challenges and unlock new potential. For example, optimizing workflow in Indian retail stores can lead to a more efficient supply chain and enhanced customer satisfaction. The success stories of Indian companies that have effectively implemented Lean Six Sigma principles highlight the transformative potential of these methodologies. These case studies serve as valuable benchmarks for other companies looking to embark on their own journey of process and quality improvement.Key Lean Six Sigma Tools for Indian Businesses

Effective Tools and Techniques for Process Enhancement

In the pursuit of operational excellence, Indian companies are increasingly turning to Lean Six Sigma methodologies. These methodologies are enriched with a wide array of tools and techniques designed to enhance business processes by improving efficiency and quality. DMAIC Framework A cornerstone for process improvement, the DMAIC framework (Define, Measure, Analyze, Improve, Control) is vital for streamlining operations. This systematic, data-driven approach is crucial for identifying and solving problems within a business process. The DMAIC framework not only helps to meticulously define and measure challenges but also facilitates control and continuous enhancement. Streamlining with Process Mapping Process mapping is instrumental in providing a visual representation of a business process. It efficiently identifies non-value-added steps and improves workflows. Through effective process mapping, organizations can streamline their activities, reducing waste and enhancing productivity. Analyzing with Data and Control Data analysis is pivotal in Lean Six Sigma for identifying trends and rooting out inefficiencies. Techniques such as regression analysis and control charts empower businesses to monitor ongoing processes closely, ensuring swift identification and rectification of any deviations from quality standards. Problem-Solving with Lean Sigma Tools Organizations leverage various Lean Sigma tools for problem-solving and continuous improvement. The Pareto chart, for instance, is widely used to prioritize issues effectively, while failure modes and effects analysis help to anticipate potential failures and devise mitigation strategies. Building Expertise with Different Belt Levels Lean Six Sigma's structured training programs, ranging from Green Belt to Black Belt, equip management teams and employees with the necessary expertise to drive process control initiatives effectively. These training programs foster a culture of quality and continuous improvement within the organization. Adopting these robust tools and techniques allows Indian enterprises to not only enhance their existing business processes but also foster a culture of continual refinement and excellence. For more insights into enhancing efficiency, explore the benefits of an integrated workplace hub.Implementing Lean Six Sigma in Office Management

Applying Lean Six Sigma Tools in Office Management

Implementing Lean Six Sigma techniques in a bustling Indian office can significantly enhance management efficiency and productivity. This involves using specific tools and frameworks to streamline business processes and encourage continuous improvement. Integrating Lean Six Sigma into office management requires a strategic approach that involves a thorough understanding of current processes. Define, measure, analyze, improve, and control – these DMAIC tools form the backbone of transformation. Start by identifying the most critical process areas that need improvement. By engaging in process mapping, office managers can meticulously outline each step, identifying problem areas and ensuring that nothing is overlooked. Once critical zones are identified, employing Lean Sigma tools like Pareto charts and failure modes is crucial to pinpoint and address the root causes of inefficiencies. Green Belts and Black Belts play a pivotal role here, applying their expertise in using regression analysis and quality control charts to drive improvements. Moreover, creating visual data representations through process mapping and stream mapping allows managers to have a clear vision of workflow dynamics. It fosters better communication and alignment within teams by making it easier to identify bottlenecks and opportunities for improvement. Continuous improvement is fueled through iterative cycles of measuring, analyzing, and refining business processes. Integrating Lean Six Sigma in office environments helps in fostering a culture of continuous improvement. It encourages employees to take ownership of their roles and become part of problem-solving processes. By regularly training staff, particularly through initiatives that equip them with the skills of a Sigma Green Belt or beyond, companies can ensure that efficiency is not just a goal but a sustained outcome. By addressing these aspects, office managers can not only enhance their operational efficiency but also contribute to the overall success of Indian companies navigating the dynamics of office life. Embracing Lean Six Sigma within office management is indeed a step towards a robust and efficient business environment.Case Studies: Success Stories from Indian Companies

Transforming Efficiency with Real-Life Experiences

In the journey of adopting Lean Six Sigma, real-world examples from Indian companies serve as both inspiration and a repository of lessons. By examining these cases, businesses can glean insights into successful strategies and potential hurdles when implementing these methodologies. This does not only provide guidance but also establishes frameworks for continuous improvement, ensuring that process efficiency and quality control are at the heart of operations.

Achieving Excellence Through Structured Frameworks

One notable example includes a major Indian manufacturing company which embraced Lean Six Sigma techniques to enhance their operational processes. By leveraging DMAIC tools and techniques, they identified key problem areas through sigma tools such as Pareto charts and control charts. With a strong focus on continuous improvement, the implementation led to significant reductions in waste, resulting in an overall improvement in product quality. The diligent use of data and analysis in these phases allowed the company to optimize their process mapping and effectively implement process control measures.

Empowering Management with Lean Sigma Methodologies

In another instance, a large Indian retail chain utilized process improvement methodologies to streamline their inventory management system. To enhance their business processes, the use of Lean Sigma and green belt participants was pivotal. By employing value stream mapping and thorough regression analysis, they managed to not only improve order accuracy but also reduce lead time significantly. This transformation cultivated a culture of continuous improvement across departments, validating the power of structured improvement projects in business management.

Harnessing Lean Six Sigma for Customer Satisfaction

An Indian IT company implemented Lean Six Sigma tools to address prevalent inefficiencies in their customer service processes. Using DMAIC's define measure and analyze phases, they pinpointed several bottlenecks and implemented change through streamlined workflows. The application of black belt expertise allowed for meticulous problem-solving initiatives that bore fruit as improved customer satisfaction rates and increased operational efficiency. Quality improvements were achieved that helped keep pace with growing client demands.

Strategic Alignment for Long-term Benefits

Lessons from these cases highlight that the key to overcoming process inefficiencies lies in embracing Lean Six Sigma methodologies. By identifying and reducing failure modes through precise sigma green methods, companies can bring about transformational changes. With a commitment to problem management and process redesign, Indian businesses stand poised for overcoming operational challenges while fostering a culture of sustained excellence. These success stories underscore the profound impact that Lean Six Sigma can have when tailored to specific Indian business contexts.

Overcoming Challenges in Lean Six Sigma Adoption

Addressing Common Roadblocks in Lean Six Sigma Integration

Implementing Lean Six Sigma in Indian companies is a journey fraught with various challenges. Even though its benefits in enhancing business processes and achieving quality improvements are well-documented, enterprises often struggle with certain aspects of its adoption.- Cultural Resistance: One of the primary hurdles is resistance to change. Employees may be apprehensive about new lean processes and sigma tools disrupting established workflows. Addressing this requires effective communication and training to illustrate Lean Six Sigma’s value in problem solving and continuous improvement.

- Lack of Trained Personnel: Without an adequate number of trained Green Belts and Black Belts, projects often face hurdles. Investing in robust training programs ensures that teams possess the requisite skills in DMAIC (Define, Measure, Analyze, Improve, Control) tools, process mapping, and data analysis.

- Data Deficiency: To achieve reliable process improvement, access to consistent and accurate data is critical. However, Indian businesses sometimes grapple with data collection issues. It’s crucial to establish mechanisms for efficient data measurement and control, paving the way for effective regression analysis and failure modes identification.

- Resource Constraints: Many organizations encounter resource limitations such as time and budgetary constraints. Building a comprehensive plan that maps out resources required across all Lean Six Sigma phases helps in mitigating such challenges.

- Sustaining Improvement: Ensuring sustainability of improvements post-project completion is a challenge. Incorporating control charts and continuous improvement strategies can help businesses maintain process efficiencies over time.